Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

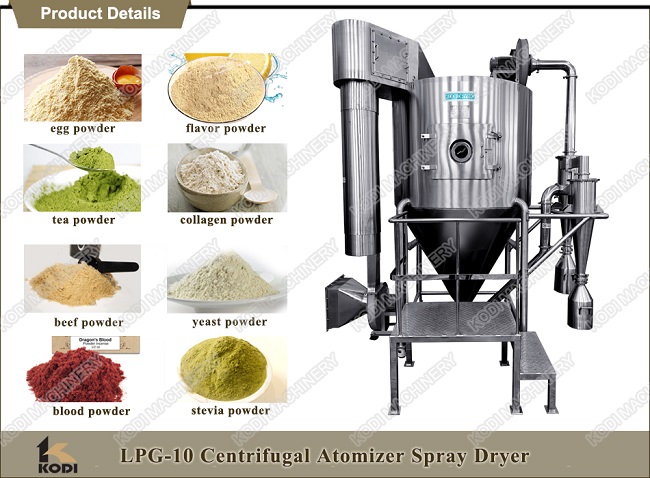

LPG-10 Spray Dryer Description

LPG-10 Model spray dryer machine is a wide applied process in liquid process shaping and drying industry. It is upgraded version of lpg-5 type spray dryer which is large chamber and two-stages cyclone separators. Particularly it is suitable for producing powder, granule or block solid product from solution, emulsion, suspending liquid and pumped paste liquid. Therefore when the distribution of granule size, final moisture, bulk density, granule shape of finished product must be conformed to accuracy standard, the spray drying is an ideal process.

Application of LPG-10 Spray Dryer

LPG-10 model lab/pilot spray dryer is widely used in foodstuff, pharmaceutical and chemical industry, such as food flavour, egg powder, amino acid product, magnesium citrate, tea, herbal extract, beef powder, protein, maltodextrin, blood, starch, food ingredients, yeast, collagen, whey, Mg citrate, humic acid, ceramic powder, vitamin, urea resin, pectin, stevia, spirulina, microalgae, gum arabic, pigment, PAC, zinc sulfate, organic magnesium compounds, vegetable juice, coffee, creamer, coconut milk, gelatin etc.

Lab Spray Drying Machine Working Principle

After filtering and heating, the hot fresh air enter into the air distributor at the top of drying chamber, distributed in spiral way uniformly from up to down. At the same time, the feeding liquid is pumped to the top atomizer, then be sprayed to extremely fine mist liquid drop. Through the short time of direct contact with hot air, the moisture evaporated at once, the solid remains to be powder. The dry powder will be discharged continuously from the bottom of drying tower and cyclone collector, the exhaust air will be discharged after cleaning.

LPG-10 Spray Dryer Machine Technical Data

|

Max Evaporation |

~10Kg/h |

Inner Dia/Height |

~1.5M/~2.85M |

|

Operation temperature |

Inlet 180℃ Outlet 90℃ |

Atomizer Dia 50mm |

Electric driving |

|

Power |

Drive:6KW |

Water consumption |

0.1m3/h |

|

Heater:27KW |

|

|

|

|

Type |

Open circle |

Feeder |

peristaltic pump |

|

Air contact |

Co-current |

Heater |

Electric heater |

|

Collection |

Cyclone |

Atomizer |

Centrifugal atomizer |

|

Packing |

Plywood box |

Power |

3Ph, 220-415V, 50/60Hz |

Successful Experience Overseas of KODI LPG 10 Spray Drying Machine