Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

YPG Pressure Spray Dryer Description

KODI YPG pressure spray dryer is suitable for solution, suspension, slurry, paste material, etc. Liquid material is atomized to small fog drops. And fog drops contact with hot air directly in the drying tower. Moisture content is evaporated instantly. So spray dryer features high efficiency, high mass transfer area, and short drying time, in general it is 5~30 seconds. Operating temperature can be adjusted according to actual situation, in general inlet air temperature is 150~500°C. And its automation control degree is control, environment solution environment can be solved.

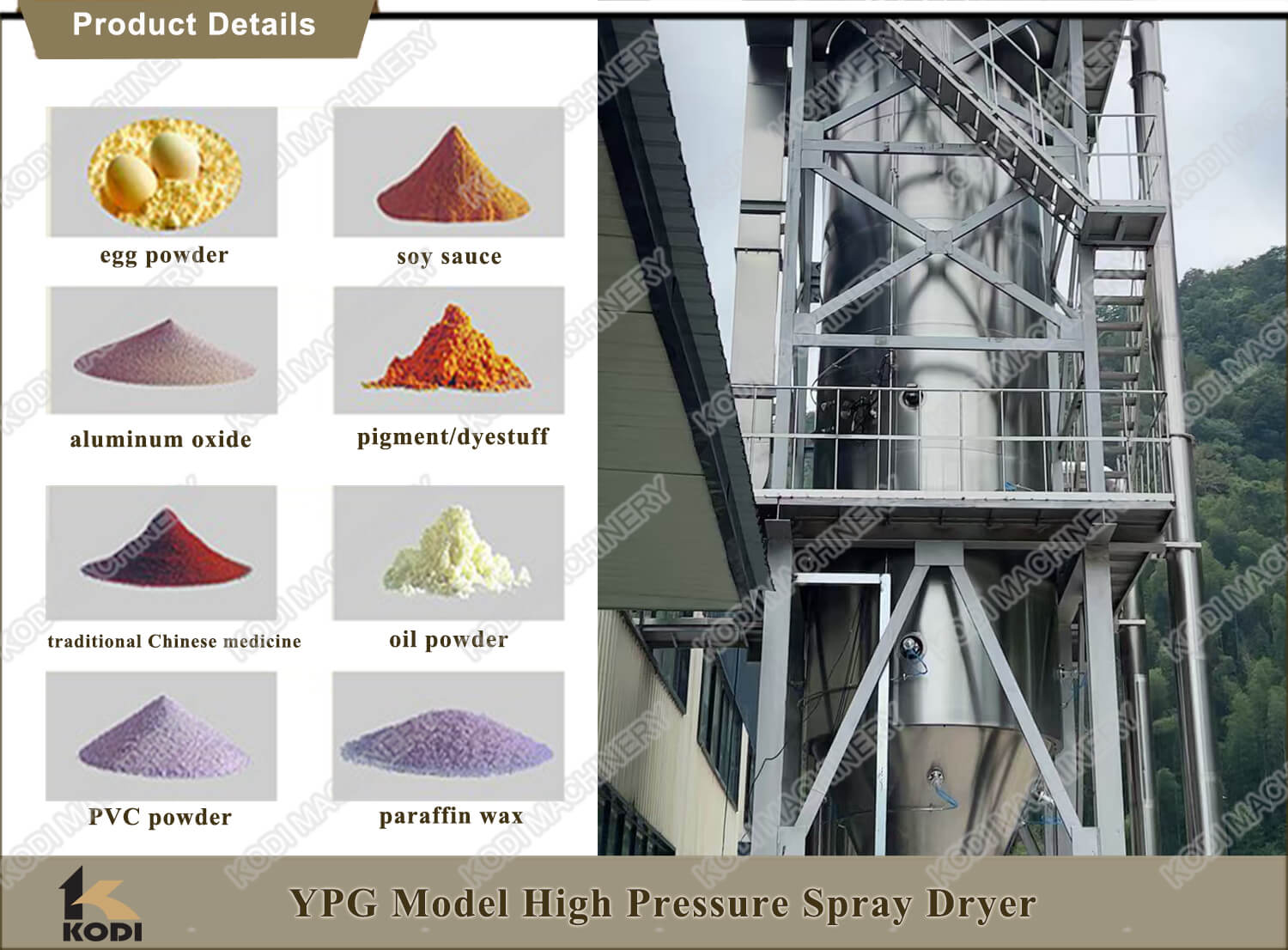

YPG Pressure Spray Dryer Application

Foodstuff industry: Amino acid and similar substance, flavoring, protein, starch, dairy products, instant coffee, fish powder, meat powder, tomato paste and so on.

Pharmaceutical Industry: Chinese patent medicine, agrochemical, antibiotics, medical drinking agent and so on.

Chemical industry: Organic catalyst, resin, synthetic washing powder, thiamin, dyestuff, intermediate of dyestuff, intermediate of dyestuff, white carbon black, graphite, ammonium phosphate and so on.

Ceramic industry: Magnesium oxide, kaolin, metallic oxide, dolomite and so on.

YPG Pressure Spray Dryer Features

1. The machine has high efficiency to collect dust

2. Without the phenomenon of adhering wall

3. Energy saving and high efficiency

4. Particularly it is suitable for thermal sensitive material

5. Short drying time

Details of YPG Pressure Spray Dryer

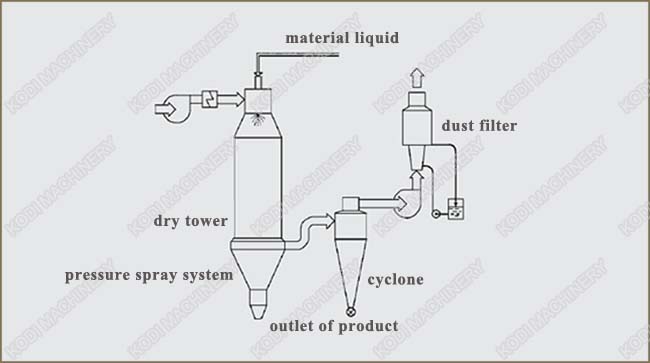

Working Principle of KODI YPG Pressure Spray Dryer

The solution, emulsion, suspension liquid or slurry are sprayed into fine beads in the hot air, going down from the top of the drying chamber to the bottom, the water will be evaporated to and the product becomes small granular product. Induce hot air from the top of drying tower, at the same time, pump the material liquid to the top of the tower by high pressure pump, the feeding solution becomes fine beads or small droplets through the pressure nozzle(s). When the droplets meet the high temperature hot air, the water will be evaporated immediately, and the material liquid is dried into dry product in a very short time, the product is discharged from the bottom of the drying tower, or from the cyclone (depend on the configuration). When the hot air contacts with the droplets, the temperature declines significantly, and the humidity increases greatly, and then will be exhausted by exhaust fan. The fine powder in the air will be collected through different separating devices There’re different fine powder separation and recovery devices, such as cyclone (the common type and various combination type), bag filter, cyclone + bag filter, cyclone + wet scrubber, and bag filter + wet scrubber etc. We should different fine powder separation and recovery devices as per the characteristics of product and requirements of customer. Depend on the product features and requirements, we might install secondary drying and cooling system (such as ZLG vibration fluid bed or pneumatic transportation), formulation system or powder sieving system etc after the spray dryer, or dehumidifier. The particle size of the product from pressure spray dryer is normally within the range of 120mesh to 20 mesh. If bigger particles are required, we suggest FL Fluidized Granulator or re-combined agglomerator.

Flow Chart of KODI YPG Pressure Spray Dryer

Successful Experience Overseas of KODI Pressure Spray Dryer

Packing and Delivery of YPG Pressure Spray Dryer

YPG Pressure Spray Dryer Technical parameters

|

Model Item |

YPG-25 |

YPG-50 |

YPG-100 |

YPG-150 |

YPG-200 |

YPG-300 |

YPG-500 |

YPG-1000-2000 |

|

|

Evaporated Capacity(kg/h) |

25 |

50 |

100 |

150 |

200 |

300 |

500 |

The index depends on the practical situation. |

|

|

Diaphragm Pump |

Power(KW) |

0.35 |

4 |

7.5 |

11 |

15 |

22 |

30 |

|

|

Pressure |

It can be adjusted from 0.6 to 5 according to the material experient. In general, the pressure will be between 1 and 3. |

||||||||

|

Heating Style |

electricity |

electricity +steam |

electricity +coal fuel (oil) hot air furnace |

||||||

|

Diameter Of Tower Body(mm) |

1300 |

1800 |

2400 |

2600 |

2800 |

3200 |

3800 |

||

|

Total Height Of Equipment (mm) |

7800 |

9200 |

11600 |

14000 |

15300 |

17100 |

19000 |

||