Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

Chilli Drying Oven Description

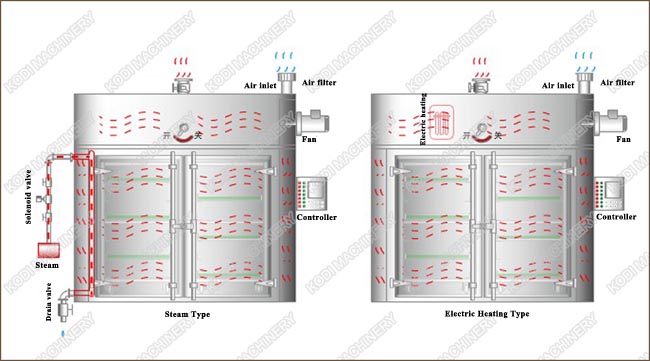

CT-C Drying Ovens or Tray dryer adopts noise elimination and thermal stable axial flow fan and automatic temperature control system. The entire circulation system is enclosed to make that the heat efficiency of the drying oven increases from 3~7% of the traditional drying oven to 35~45% of the present one. The highest heat efficiency can be up to 50%.The successful design of CT -C hot air circulation oven makes that the hot air circulation drying oven in our country reach the advanced level in the world. It saves energy and increases the economic benefit.In1990, the medical management bureau of the State issued the industry standard and the uniform type is RXH.

Chilli Drying Oven Application

This drying oven is suitable for the material and product hot solidification and dry de-watering in the pharmaceutical, chemical, food, farming, side-product, aquatic product, light industries, heavy industries and others industries. Such as: raw material medicine, crude drug, prepared herbal medicine of Chinese traditional medicine, plaster, powder, particle, drinking agent, pill, packing bottle, pigment, dyestuff, de-watering vegetable, dried fruit piece, sausage, plastics, resin, electric component, baking varnish and etc .

Chilli Dring Oven Features

1. Three kinds of heat source are used for heating : electricity, steam+ electricity.

2. Operation temperature: steam,50-140°C. Max.150°C, electricity,50~350°C. The temperature can be controlled automatically. Moreover it can be recorded through recorder.

3. The inner wall of oven body is fully welded. Each transition adopts circular arc and no dead.

4. The seal property of whole machine is good. Being adopted unique guide rail seal apparatus, the seal property can be guaranteed.

5. The air inlet is equipped with high effective air filter and the damp exhaust outlet is equipped with middle effective air filter.

6. The double doors of oven adapt mechanical interlock apparatus.

7. All parts inside the oven can be assembled and disassembled quickly in order to clean conveniently.

8. The control system has test display and touch screen for your choice.

9. The whole machine is in conformity with the requirements of GMP.

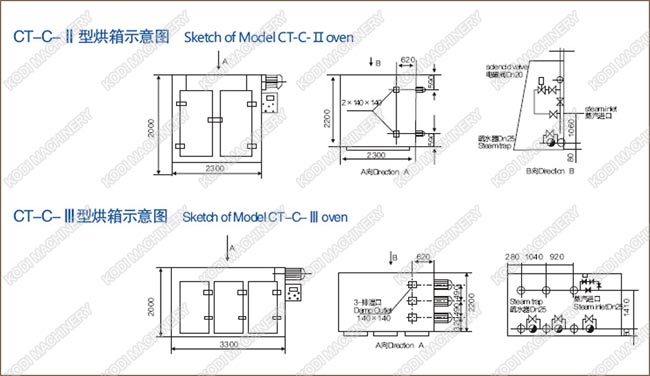

Drawing and Flow Chart of Dring Oven

Packing and Delivery of Dring Oven

Chilli Drying OvenTechnical Parameters

|

Model |

Drying capacity(kg/lot) |

Electric heating power(kw) |

Fan power(kw) |

Overall dimensions W*D*H(mm) |

Equipped drying shelf(set) |

Drying plate equipped (pc) |

Temperature automatic control box |

Total weight(kg) |

|

CT-C-O |

60 |

6-9 |

0.45 |

1380*1200*2000 |

1 |

24 |

available |

820 |

|

CT-C-I |

120 |

15 |

0.45 |

2260*1200*2000 |

2 |

48 |

available |

1580 |

|

CT-C-II |

240 |

30 |

0.45*2 |

2260*2200*2000 |

4 |

96 |

available |

1800 |

|

CT-C-II A |

240 |

30 |

0.45*2 |

4280*1200*2270 |

4 |

96 |

available |

1880 |

|

CT-C-III |

360 |

45 |

0.45*3 |

2260*3200*2000 |

6 |

144 |

available |

2100 |

|

CT-C-III A |

360 |

45 |

0.45*3 |

3240*2200*2000 |

6 |

144 |

available |

2210 |

|

CT-C-IV |

480 |

60 |

0.45*4 |

4480*2200*2270 |

8 |

192 |

available |

2800 |

|

CT- I |

120 |

15 |

1.1 |

2480*1200*2375 |

2 |

48 |

none |

1220 |

|

CT-II |

240 |

30 |

1.1 |

2480*2200*2438 |

4 |

96 |

none |

1530 |

|

CT-III |

360 |

45 |

2.2 |

3430*2200*2620 |

6 |

144 |

none |

2110 |

|

CT-IV |

480 |

60 |

2.2 |

4460*2200*2620 |

8 |

192 |

none |

2300 |