Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

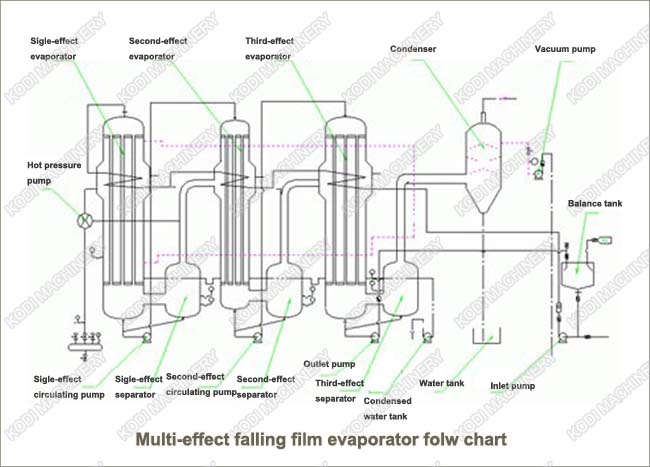

Description of Falling Film Evaporator

Multiple-effect falling film evaporator concentrates the solution by means of vaporizing the thin solution through film-falling principle. It introduces continuous production and it features in high concentration ratio (1/5-1/10), large viscosity scope (400CP), good heat-transferring effect, large processing capacity, etc. In this case, it can be introduced on vaporizing materials which are of high heat sensibility, high concentration, high viscosity, and corrosive characteristics.

Evaporator System Components

Evaporator in every stage; separator in every stage; condenser, heat pressure pump, sterilizer, insulating tube, material transfer pump in every stage; condensate water pump, work table, electric meter control cabinet, valve, pipeline etc.

Multi-effect Evaporator Applications

Multi-effect falling film evaporator is widely used for concentratingherbal extraction, Western medicine, corn slurry, glucose and maltose in starch industry, juice and MSG liquid in food industry, milk liquid in dairy industry, as well as lees filtrate in alcohol industry.

It is especially suitable for low temperature vacuum concentration of heat sensitive substances. It can carry out continuous sterilization and concentration. After carefully calculated and precisely designed and improved by professional designers of KODI Company. It has more features and benefits than the original one. The period of being heated of materials is short and the evaporation temperature is low. It has small influence on the product’s color, flavor and nutritious content which is especially applicable to concentration of milk etc. heat sensitive substances.

Characteristics of KODI Falling Film Evaporator

- High heat transfer efficiency realized for the heating system even heated with steam and feed liquid in flow evaporate The equipment has smaller energy consumption. Steam consumption and cool water circulation amount if equip with heat pressure pump.

- Feed liquid evaporated while accelerated flow downward along the pipe wall that suitable for evaporation and concentration of high viscosity material

- Liquid heat in very short time for it inner film evaporated in every tube That make the equipment very fit food concentration can maximum protect food nutritious.

- Whole process operated under vacuum condition which meet the sanitary requirement and environmental protection requirement. Meanwhile can significantly reduce the evaporation temperature. If equipped with heat pressure pump, part of second steam will re-sucked and mixed with live steam .Steam pass through pump into heating shell, steam rapidly spread make liquid soft heated, is very suitable for concentration of heat sensitive products.

- Equipment suitable for evaporation and concentration of formability material Liquid film evaporated in heating tube formed liquid-vapor separate. Big part of feed extracted from the bottom of cylinder. Only small part of feel liquid and all second steam enforced to separate Feed liquid not in big impacted no foam formed in the whole process.

- Equipment can also sterilize food Feed liquid flow to sterilizer after preheated .Temperature up to 94°Cand lasting for 24 seconds. Then flow into first stage. Liquid evaporate in few seconds then temperature drop at once.

- Can equip with CIP cleaning system, achieve clean in spot. Completed set operated easy without dead angle

- Can continuous feed material and discharge material

- Can equip with automatic system, achieve automatic control of inter and outlet material, discharge viscosity and cleaning.

- Can equip with protection facilities in case of suddenly blackout, break down which will cause trouble with heat sensitive products other safeties, alarm facilities can achieve automatic operate and control.

Multi-effect Evaporator Advantages

- This equipment is of higher heat-transferring ratio, so the heat difference requested is small.

- It can be combined into double, triple, quadruple, or quintuple-effect evaporating system on the basis of different materials characteristics and evaporating results.

- It can be used as waste-heat evaporator with the resources of waste steam from bundle dryer, disc dryer or other heat resources with low thermal value such as condensate steam.

- Raw steam consumption can be greatly reduced for energy saving.

- It is economically beneficial when waste steam can be completely used and raw steam is saved.

Falling Film Evaporator Main Parameters

|

Model Parameter |

NS-300 |

NS-600 |

NS-700 |

NS-1250 |

NS-2000 |

NS-2500 |

|

Moisture evaporation(kg/h) |

300 |

600 |

700 |

1250 |

2000 |

2500 |

|

Material disposal quantity |

400 |

800 |

940 |

1680 |

2688 |

3360 |

|

Inlet material strenght(%) |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

|

Outlet material strenght(%) |

45-48 |

45-48 |

45-48 |

45-48 |

45-48 |

45-48 |

|

First-effect evaporating temp. (℃) |

68-72 | 68-72 |

68-72 |

68-72 |

68-72 |

68-72 |

|

Second-effect evaporating temp. (℃) |

|

|

45-52 |

45-52 |

45-52 |

45-52 |

|

Steam consumption(kg/h) |

2 |

4.2 |

5 |

9 |

14 |

18 |

|

Cooling water consumption (kg/h) (16℃inlet,40℃outlet) |

5 |

9 |

14.2 |

15 |

18 |

24.5 |

|

Model Parameter |

NS-3000 |

NS-3200 |

NS-5000 |

NS-6400 |

NS-8000 |

NS-10000 |

|

Moisture evaporation(kg/h) |

3000 |

3200 |

5000 |

6400 |

8000 |

10000 |

|

Material disposal quantity |

4032 |

4300 |

6720 |

8500 |

11000 |

13800 |

|

Inlet material strenght(%) |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

≥11.5 |

|

Outlet material strenght(%) |

45-48 |

45-48 |

45-48 |

45-48 |

45-48 |

45-48 |

|

First-effect evaporating temp. (℃) |

68-72 |

68-72 |

68-72 |

68-72 |

68-72 |

68-72 |

|

Second-effect evaporating temp. (℃) |

45-52 |

55-60 |

55-60 |

55-60 |

55-60 |

55-60 |

|

Third-effect evaporating temp. (℃) |

|

44-48 |

44-48 |

44-48 |

44-48 |

44-48 |

|

Steam consumption(kg/h) |

21 |

30 |

32 |

40 |

48 |

55 |

|

Cooling water consumption (kg/h) (16℃inlet,40℃outlet) |

28 |

31 |

44.4 |

45 |

60 |

83 |

Packing and Delivery

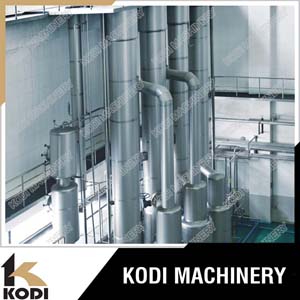

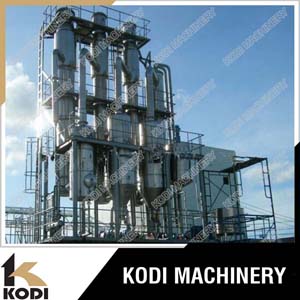

Customer Site

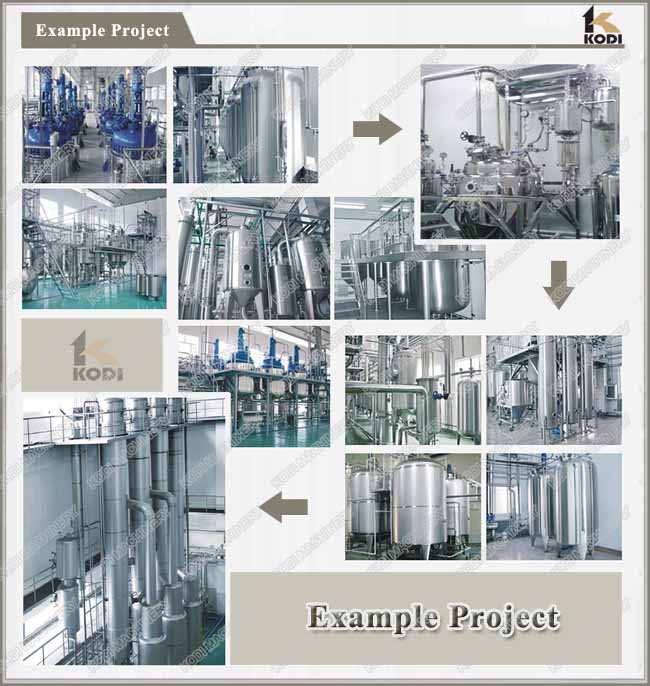

Sucessful Project

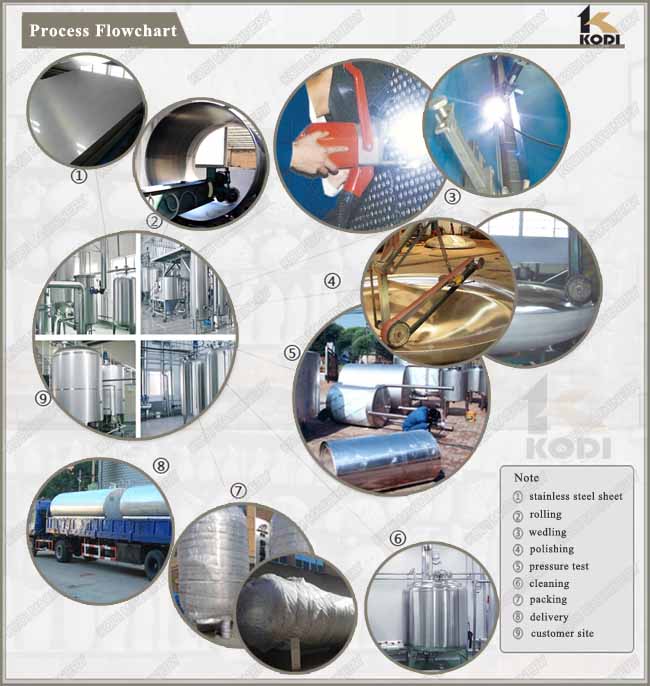

Process Flow Chart