Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

FL Fluid Bed Granulator Application

FL fluid bed granulator is mainly used for the operations of mixing, granulating, drying and coating of granule "Top Spraying", etc of powder material in pharmaceutical industry, foodstuff industry, chemical industry, etc. Such as granule of tablet, granule for quick resolving drinking, condiment.

The machine is manufactured in accordance with JB20014-2004 Fluid-bed Granulator In Medicine

Features of FL Fluid Bed Granulator

1. Mixing-granulating-drying in one-step.

2.Adopting double chamber filtering bags system, remove dust completely.

3.Adopting multi-fluid nozzle, it guarantees that the formed granule is uniform and the content of powder is very low.

4.Can choose 2 bar explosive-proof design

5.Designed, manufactured and laid out by GMP

Working Principle of FL Fluid Bed Granulator

The Powder granule the container (fluidization bed)appear the state of fluidization. It is preheated and mixed with clean and heated air. At the same the solution of adhesive solvent is fogged and sprayed into the container. It makes the Same particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulating is evaporated and the adhesive is solidification. The process is carried out continuously. Finally it forms ideal, uniform and porous granules.

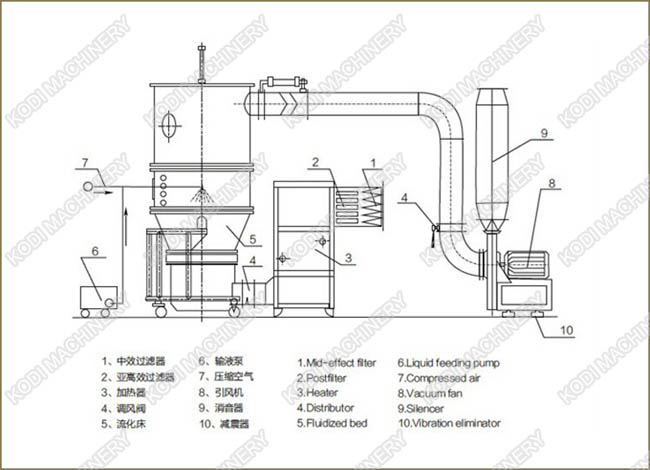

Drawings of FL Fluid Bed Granulator

Successful Experience Overseas By KODI FL Fluid Bed Granulator

Delivery of KODI FL Fluid Bed Granulator

Technical Parameters of FL Fluid Bed Granulator

|

Item |

specification |

||||||||||||||

|

Name |

Unit |

3 |

5 |

15 |

30 |

45 |

60 |

90 |

120 |

150 |

200 |

300 |

500 |

800-1000 |

|

|

Container Volume |

L |

12 |

22 |

45 |

100 |

155 |

220 |

300 |

420 |

550 |

670 |

1000 |

1500 |

By client

|

|

|

Capacity |

kg/batch |

3 |

5 |

15 |

30 |

45 |

60 |

90 |

120 |

150 |

200 |

300 |

500 |

||

|

Steam |

Pressure |

Mpa |

0.4-0.6 |

||||||||||||

|

Consumption |

kg/h |

10 |

18 |

35 |

60 |

99 |

120 |

130 |

140 |

161 |

180 |

310 |

400 |

||

|

Power of fan |

kw |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

22 |

30 |

45 |

||

|

Power of electricity heater |

kw |

6 |

9 |

|

|

|

|

|

|

|

|

|

|

||

|

Noise |

dB |

Not more than 75dB Separated of fan |

|||||||||||||

|

Compressed air |

Pressure |

Mpa |

0.6 |

||||||||||||

|

Consumption |

m 3 /min |

0.3 |

0.3 |

0.6 |

0.6 |

0.6 |

0.9 |

0.9 |

0.9 |

0.9 |

1.1 |

1.3 |

1.5 |

||