Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

Description of Stainless Steel Mixing Tank

Blending preparation stainless steel tank , also called as materials blending tank or materials mixing tank , have the advantages such as being energy saving , corrosion-proof , strong productivity and easy to clean etc .

And it is mainly used for blending and homogenizing of dairy products , sugar , other elements and various medicines , as an indispensable equipment for dairy products, beverage and pharmacy manufacturers . It is made of SUS304 or 316 stainless steel and it in accordance with GMP production standard.

Stainless steel mixing tank is a type of tank makes enzymes decompose in optimum conditions and converts certain substances into some other substances with better performances through action of enzymes . The jackey can be used for heating or cooling , attached with external heat preservation layer

Application of Stainless Steel Mixing Tank:

1.Cosmetic and daily chemical product: Cosmetic cream, lotion, shampoo, detergent, health care product, gel, Laundry detergent, hand sanitizer, armpits lotion etc.

2.Pharmaceutical product: Ointment, Ice packs, injection liquid, penicillin etc

3.Food : Salad, mayonnaise, peanut butter, sesame butter, buttery, Animal fat, iced products, healthy food etc.

4. Beverage: Fruit Juice, Milk Juice etc.

5.Chemical: Paints, Pigments, dyes, phto solvents, Rubber and resin, pesticides ,Shoe polish, general chemicals etc.

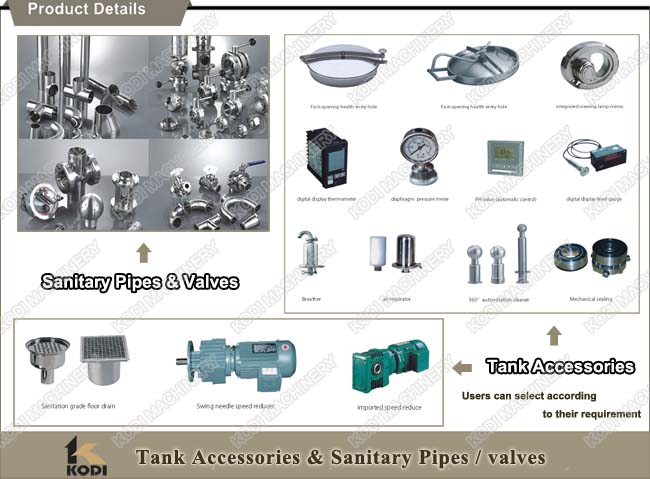

Structure of Stainless Steel Mixing Tank

1. Electric heating

2. Jacketed with insulation layer

3. With or without mixing system. Mixing device: Paddle, Anchor, or spiral agitator (optional and changeable to meet customer demands).

4. Material: SUS 304 or SUS 316.

5. Outer casing surface: Mirror polishing / 2B original sub-gloss / 2B frosted sub-gloss; Inner surface (bladder and tank): Mirror polishing (Roughness: Ra≤ 0.4μ M ).

6. Liquid level gauge: Digital metre or glass gauge optional.

7. Thermometer: Optional. Temperature indication ranges from 0 to 100º C.

8. Sample valve optional

19.CIP cleaning: T-shaped 360° Rotational CIP cleaning ball.

10. Man-hole equipped.

Performance and Characteristicsof Stainless Steel Tank

1.High speed disperser. Might mixing and disperse viscously, solid and liquid etc. Various kind of raw material will be dissolve which is such as AES, AESA LSA, during liquid production which can save energy consumption and shorten production the and shorten production period.

2.Main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed to produce liquid washing products.

3.Finished products can be discharged by Disc-valve or suitable to all liquid wash products.

Main Parameters of Stainless Steel Tank

|

Effective volume |

Dimension of tank |

Total height |

Diameter of inlet & outlet |

Heat preservation layer |

Motor power |

Blending speed |

|

(L) |

(mm) |

(mm) |

(mm) |

(mm) |

(kw) |

(r/min) |

|

500 |

840*1000 |

2750 |

60 |

38 |

0.55 |

Common rotation speed 35,43,60 ; stepless speed reducer or dual-speed reducer are also available |

|

600 |

920*1000 |

2850 |

60 |

38 |

0.55 |

|

|

700 |

990*1000 |

2850 |

60 |

38 |

0.55 |

|

|

800 |

950*1220 |

3000 |

60 |

38 |

0.55 |

|

|

900 |

1010*1220 |

3000 |

60 |

38 |

0.55 |

|

|

1000 |

1060*1220 |

3150 |

60 |

51 |

0.75 |

|

|

1500 |

1160*1500 |

3350 |

60 |

51 |

0.75 |

|

|

2000 |

1340*1500 |

3410 |

60 |

51 |

1.1 |

|

|

3000 |

1410*2000 |

4000 |

60 |

51 |

1.5 |

|

|

4000 |

1620*2000 |

4250 |

60 |

51 |

1.5 |

|

|

5000 |

1810*2000 |

4300 |

60 |

51 |

2.2 |

|

|

6000 |

1980*2000 |

4550 |

60 |

51 |

2.2 |

|

|

7000 |

1930*2440 |

5000 |

60 |

51 |

2.2 |

|

|

8000 |

2060*2440 |

5000 |

60 |

51 |

3 |

|

|

9000 |

2180*2440 |

5050 |

60 |

51 |

3 |

|

|

10000 |

2300*2440 |

5050 |

60 |

51 |

3 |

|

|

12000 |

2270*3000 |

5600 |

60 |

51 |

4 |

|

|

15000 |

2530*3000 |

5700 |

60 |

51 |

4 |

|

|

20000 |

2640*3660 |

6400 |

60 |

51 |

5.5 |

Remark: we can meet the requirement as per your drawings or samples

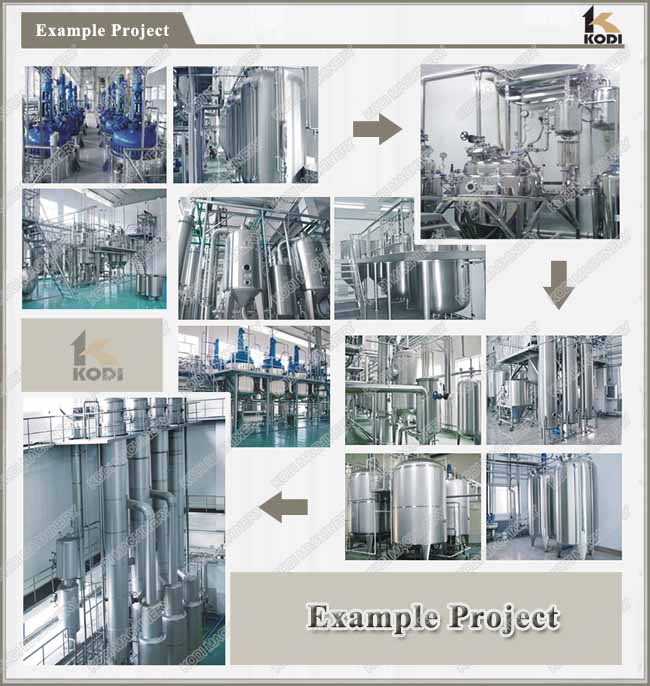

Sucessful Project

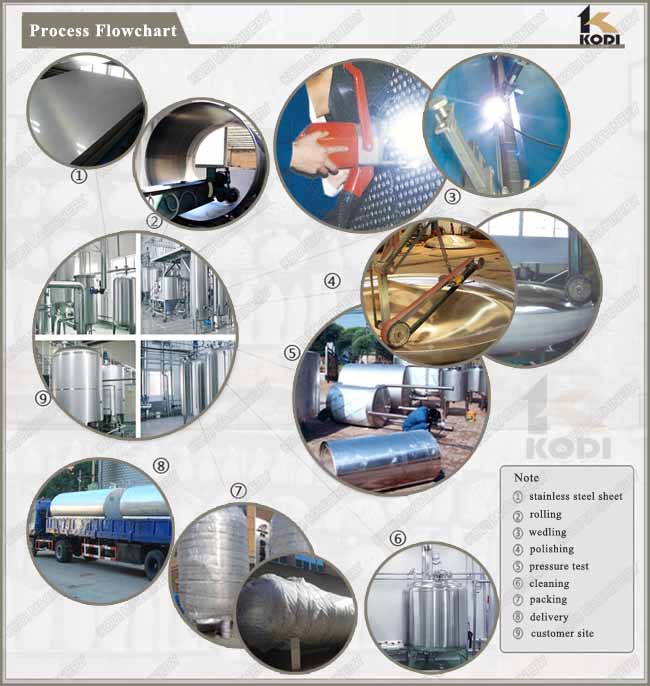

Extracting Tank Process Flow Chart