Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

Description of Herbal Extraction Spray Dryer

Chinese herbal medicine extract is refined from root, stem and leaves of plants, and contains high sugar especially from alcoholization process, which is easy melted at high temperature. Normal centrifugal spraying cannot meet its drying requirements. For that reason, our company organized a group of technicians to develop such a dryer especially used for Chinese herbal medicine extract after repeated calculations and countless tests on the basis of our experience to make spraying dryer and collect advantages of same kind of dryers from both domestic and abroad.

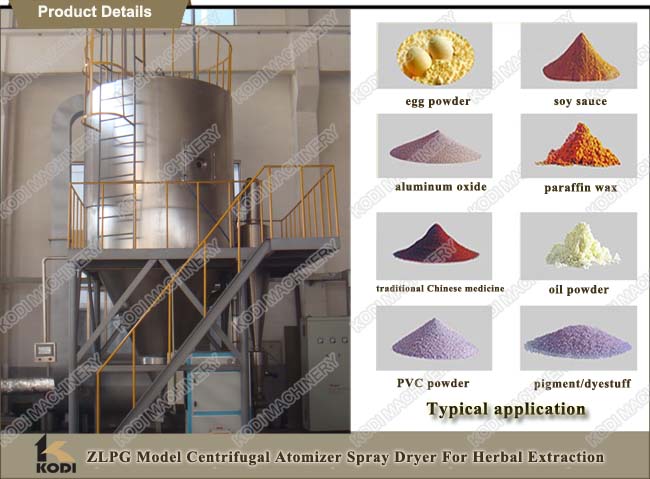

Application of KODI Herbal Extraction Spray Dryer

1. Liquid, paste, soupy, material, like: salty essence, broth essence, soy sauce powder, amino acid, vinegar powder.

2. Food additives, fish protein, egg powders, mushroom powder, maltodextrin, etc.

Final Product of KODI Spray Dryer

Herbal Extraction Spray Dryer Features

1. This unit uses higher linear speed centrifugal atomizer, link speed achieves 16000rpm, it is suitable for drying and granulating high solid content liquid state materials.

2. Uses eliminated dehumidification and cooling technology, it is suitable for viscosity, oiliness, heat sensitivity, moisture property material drying and granulating.

3. Uses centralized purification collection, finished product can be collected in clean room, which achieves high standard of hygienic requests, and avoid the pollution of ambient air.

4. This unit uses three levels independent discharging system and multiple stages washing spray technology, enhance the recovery of products.

5. Uses whirlwind cutting in and inlet air broom the wall to prevent materials sticking on the inside wall.

6. This unit is match with infrared temperature measurement, intelligent automatic control technology. Through real temperature feedback, automatic adjusts liquid material feed capacity, guarantees the finished products’ quality. By the function of program design, encrypt, correct, etc. And PLC operation system, effectively enhance the accuracy of process parameter execution, thus guarantee the products quality and improve the modern product management level.

7. In order to facilitate the operation of this unit, according to actual situation, the heating sources can be electricity, steam, fuel, gas, etc.

8. Jam prevent technology is used.

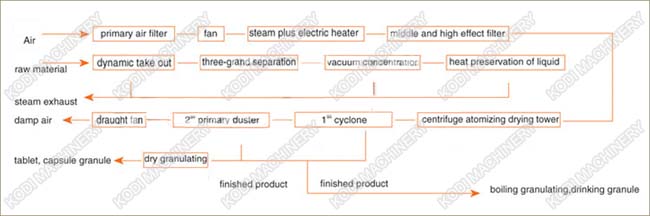

Working principle

Packing and Delivery of KODI ZLPG Spray Dryer

Successful Experience Overseas of KODI ZLPG Spray Dryer

Technical parameters

|

Model |

ZLPG-5 |

ZLPG-10 |

ZLPG-25 |

ZLPG-50 |

ZLPG-80 |

ZLPG-100 |

ZLPG-150 |

ZLPG- 200 |

ZLPG- 300 |

|||||

|

Water evaporation(kg/h) |

5 |

10 |

25 |

50 |

80 |

100 |

150 |

200 |

300 |

|||||

|

Liquid input amount(kg/h) |

6-7 |

12-14 |

25-34 |

50-68 |

80-108 |

100-135 |

150-203 |

200-270 |

300-406 |

|||||

|

Capacity (kg/h) |

1-2 |

2-4 |

4.8-7.2 |

9.2-14 |

14.8-22.4 |

18.4-28 |

28-42 |

36.8-56.4 |

55-85 |

|||||

|

Solid content of liquid material(%) |

18-25% |

|||||||||||||

|

Water content of final product(%) |

3-5% |

|||||||||||||

|

Power(kw) |

36 |

45 |

63 |

99 |

132 |

153 |

204 |

246 |

330 |

|||||

|

Heat source |

Steam + electricity |

|||||||||||||

|

Collecting way of product and its efficiency |

Two grade cyclone separator or one-grade cyclone separator and one grade film duster≥95% |

|||||||||||||

|

Auto-control instrument |

Indicator of hot air temperature and outlet air temperature, temperature auto regulating controller |

|||||||||||||

|

Inlet air temperature(℃) |

150-200 |

|||||||||||||

|

Outlet air temperature(℃) |

80-100 |

|||||||||||||

|

Overall dimension (mm) |

L |

5000 |

5500 |

7000 |

8000 |

9800 |

11000 |

12200 |

14100 |

15000 |

||||

|

W |

3000 |

3500 |

4000 |

5000 |

5700 |

6200 |

7000 |

7800 |

9000 |

|||||

|

H |

4500 |

4600 |

5200 |

6500 |

7600 |

8100 |

9000 |

9850 |

11100 |

|||||