Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

FG Fluid Bed Dryer Applications

1,Use screw to extrude and vibrate granule and granulate the granule with the method of humidity, high speed and mixing

2,Suitable for drying humidity block or powder raw material in the fields such as pharmaceutical, foodstuff, feed stuff, chemical industries and so on

3,The raw material that large in granule and small in block and having adhesive property

4,Suitable for raw materials, its volume will be changed when dry, such as giantarum, polyacrylamide, etc.

Features of FG Fluid Bed Dryer

1,The structure of fluidization bed is round so as to avoid the dead angle

2,Inside the hopper there is a stirrer in order to avoid agglomeration of raw material and forming canal of flow

3,The granule is discharged through the method of turning over. In this way it is very convenient. The discharging system can be designed as required too

4,It is operated at the condition of negative pressure and seal. The air is filtered. Therefore it is simple in operation and convenient in clean. It is an ideal equipment that is in conformity with the requirements of GMP.

5,The drying speed is fast and the temperature is uniform. In general, the drying time is 15-45 minutes each batch

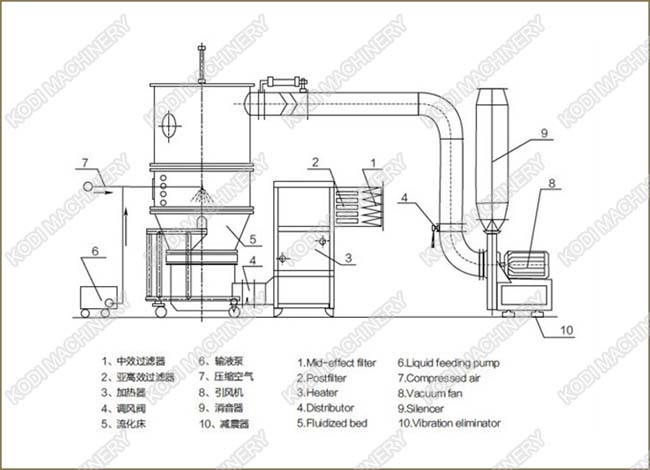

Working Principle of FG Fluid Bed Dryer

When air is purified and heated, it is introduced from the bottom of induced-draft fan and passed through the screen plate of raw material. In working chamber, the state of fluidization is formed through stirring and negative effect. The moisture is evaporated and removed rapidly and the raw material is dried quickly.

Overseas of FG Fluid Bed Dryer

Packing and Delivery of FG Fluid Bed Dryer

Technical Parameter of FG Fluid Bed Dryer

|

Item |

Unit |

Machine type |

||||||||

|

3 |

5 |

30 |

60 |

120 |

200 |

300 |

500 |

|||

|

Material tank |

Diameter |

Mm |

300 |

400 |

700 |

1000 |

1200 |

1400 |

1600 |

1800 |

|

Volume |

L |

12 |

22 |

100 |

220 |

420 |

670 |

1000 |

1500 |

|

|

Production capacity |

Min. |

Kg/batch |

1.5 |

4 |

15 |

30 |

80 |

100 |

150 |

250 |

|

Max. |

Kg/batch |

4 |

6 |

36 |

72 |

140 |

240 |

360 |

600 |

|

|

Steam consumption |

Kg/batch |

12 |

23 |

70 |

140 |

211 |

282 |

366 |

465 |

|

|

Compressed air consumption |

M³/min |

0.3 |

0.3 |

0.3 |

0.6 |

0.6 |

0.9 |

1.1 |

1.6 |

|

|

Fan power |

Kw |

2.2 |

2.2 |

5.5 |

11 |

18.5 |

22 |

30 |

45 |

|

|

Temperature |

℃ |

Normal temperature ~ 120℃(auto-adjusting) |

||||||||

|

Product rate |

% |

>99 |

||||||||

|

Final moisture content |

% |

~ 0.2 |

||||||||

|

Noise |

dB(A) |

≤75 |

||||||||

|

Main machine height |

Mm |

2100 |

2300 |

2500 |

3000 |

3300 |

3800 |

4000 |

4400 |

|