Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

Characteristics of Vacuum Concentrator

1. Self-control type triple effect concentrator is intellectual product newly developed by KODI company

Has such characteristics as intellectual program digital display, automatic controlled temperature, liquid level, steam pressure, vacuum degree, material density, concentration, automatic material feeding and ointment

collection

2. All controls are controlled by PIC control board

3. All technical parameters are displayed on touch screen

4. Automatic operation can be programmed so that equipment can eliminate such problems as running away and boiling of material due to too high vacuum and material and agglomeration due to too high steam temperature, which are caused by improper manual operation.

5. Can eliminate fears of disturbance during safety production and can also ensure safety production, product quality and energy consumption so that production capacity is greatly enhanced. Also fundamental device for constructing modernization.

External Circulation Vacuum Concentrator Applications

1. Applicable for concentration of liquid materials for Herbal extraction, Medicines, glucose, starch, monosodium glutamate, dairy food and chemical industry, especially ideal for low temperature vacuum concentration of heat sensitive substances.industrial organic solvents (such as alcohol) recovery for vacuum concentration to small-volume, variety and more heat-sensitive materials.

2. After carefully calculating and designing, compared with before, equipment has more characteristics and benefits. Customers can choose concentrators with technical parameters indicated according to quantity of materials for concentration.

Benefits of Vacuum Concentrator

1. Energy-saving, taking SJN-1000B type for calculating, for a year, approximately 5000 tons of steam, and cooling water of hundreds of thousands of tons can be saved, thus, cost of at least 40,000 USD is saved.

2. The concentrator adopts external heating natural cycling mode and negative pressure evaporating mode, with instant evaporation and great concentrated specific gravity up to 1.3 (common soaked Chinese medicine creams). Open boiler is not needed to reclaim creams.

3. The concentrator adopts tri-effect simultaneous evaporation and uses second time steam repetitively. Therefore, the energy can be saved by 70% when compared with single-effect concentrator. Within a year, the investment saved can be up to total investment on the concentrator.

4. All parts of the vacuum concentrator contacting with materials are made of (AISI304) stainless steel according to requirements in laws related to medicines and foods, and requirements of cGMP. It has nice appearance. And heater and evaporator have external heat preservation layers. The heat preservation layers are made of stainless steel and polished with semi-luster for nice appearance in layout of workshop.

Main Parameters of External Circulation Vacuum Concentrator

|

Model Parameter |

SJN-500 |

SJN-1000 |

SJN-1500 |

SJN-2000 |

SJN-3000 |

SJN-5000 |

|

Capacity |

≥500 |

≥1000 |

≥1500 |

≥2000 |

≥3000 |

≥5000 |

|

Steam consumption |

≤275 |

≤550 |

≤825 |

≤1100 |

≤1650 |

≤2750 |

|

Coolwater consumption |

14 |

28 |

42 |

56 |

84 |

140 |

|

Vacuum exhaust volume |

150 |

240 |

375 |

480 |

600 |

1050 |

|

First-effect heating area |

8.0 |

12.5 |

18.5 |

25 |

37 |

62.5 |

|

Second-effect heating area |

12.5 |

18.5 |

25.0 |

32.5 |

46 |

78 |

|

First-effect evaporating temp. |

75-85 |

|||||

|

Second-effect evaporating temp. |

55-65 |

|||||

Sucessful Project

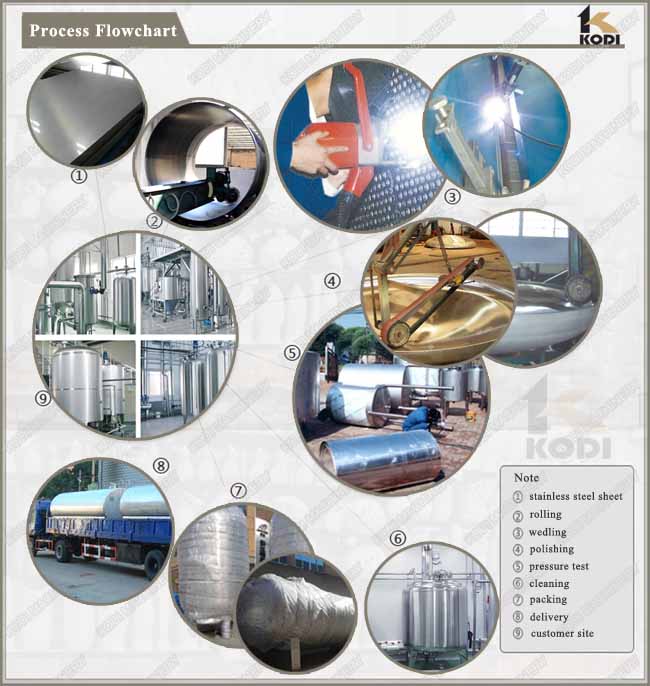

Extractor Process Flow Chart