Changzhou Kodi Machinery Co.,Ltd.

Factory address:No.2 Hongzhi Road, Tianning District, Changzhou, Jiangsu, China

Marketing office:7F, Tongjiang Road 398-1#, Xinbei District, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Mob: +86 15995073588(Wechat & Whatsapp)

E-mail: info@kodichina.com

Web: www.kodichina.com

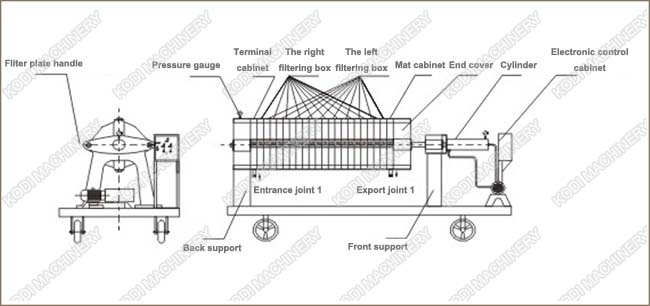

Description of Gelatin Cotton Cake Filter Press

Gelatin cotton cake filter press using recycled fiber material as filter media to remove traces of oil in the liquid material, mechanical impurities, suspended complexes and other impurities, so that filtered liquid clear and transparent.

Characteristic of Cotton Cake Filter Press

Cotton cake filter press Plate frame dimension is 400mm or 500mm, hydraulic operating and easy to operate. It proves that cotton plate runs better than paper plate filter.This cotton filter press has a bigger filter area (compare to stainless steel multi layersfilter), convenient operation and maintenance of the characteristics of the machine frame with a circular structure of the frame and the filter performance is more excellent. Aircraft aluminumframe material and reinforced polypropylene two kinds of and can increase or reduce the number of frame, can be applied to different liquid filtration.

The Main Fitting of Gelatin Fliter Press

1. Controlled by PLC and reserves DCS remote interface

2. Automatic Hydraulic maintaining pressure

3. Main beam is made of high quality carbon steel with sand blasting processing and it is of high intensity and corrosion resisting

4. Pure reinforced PP filter plate resistes to stronger corrosion and endure high pressure and service longer

5. Every plates is tested under high closing pressure

6. Automatically discharging make it perform better efficient

Application of Cotton Cake Filter Press

The cotton cake filter pressis widely applied in gelatin and collagen filtration system, which works fast and is convenient in operation. It also can be used for fermentation, enzymes, food and beverage, and other high precision requirement industries.

Working Principle

The feed enters the press at the corner of the plate, Then, the feed travels the path of least resistance, which has filter media inserted between the plates, and the void between the plates is filled with the slurry, as the liquid passes through the filter media, and travels up to the outlet port at the top of the plate. This liquid is referred to as the "filtrate", and is discharged from the press. The solids remain in the void between the plates, until the plates discharge the filtered solids. So it can make the solid- liquid separation come true.