Changzhou Kodi Machinery Co.,Ltd.

Marketing office: 7F, Tongjiang Road 398-1#, Xinbei District, Changzhou 213022 China

Factory address:Zhenglu Industrial Park, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Hotline: +86 15995073588

E-mail: info@kodichina.com

Web: www.kodichina.com

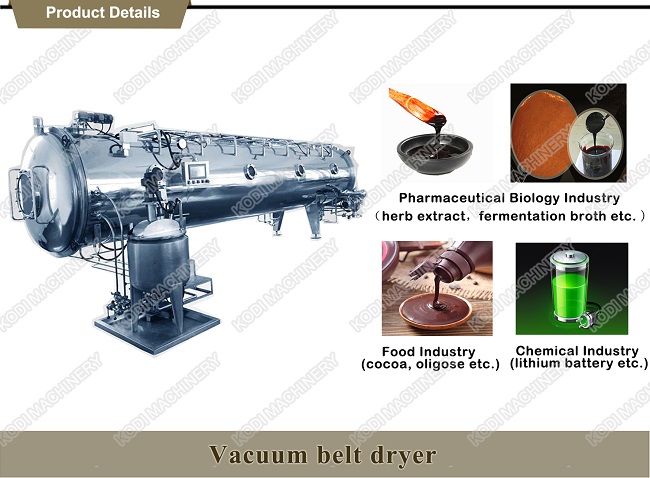

Description of Vacuum belt dryer

Vacuum belt dryer is a new type of drying equipment developed in China in recent years. It is widely used in extracts of most natural botanical drugs, especially suitable for drugs with high viscosity, easy agglomeration, thermoplasticity, and heat sensitivity or not The spray drying method can be used for continuous feeding and continuous discharging. The whole process of feeding, drying and discharging is sealed and carried out under high vacuum, without contact with the external environment, and meets GMP requirements.

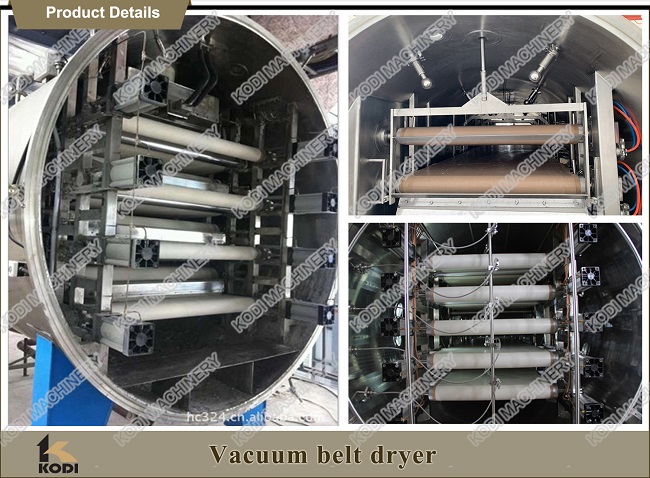

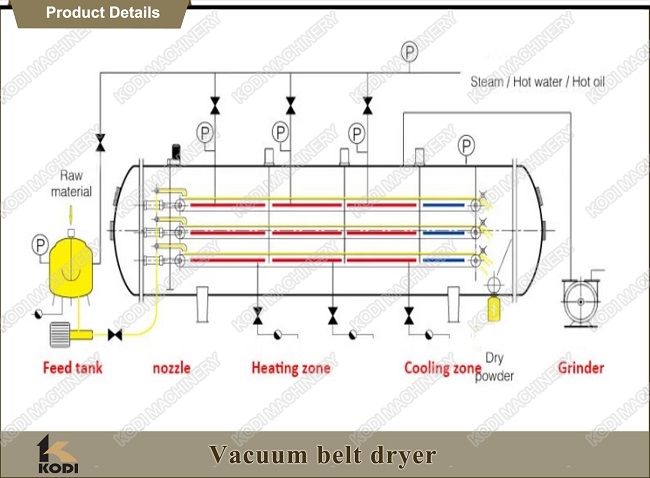

Working principle of Vacuum belt dryer

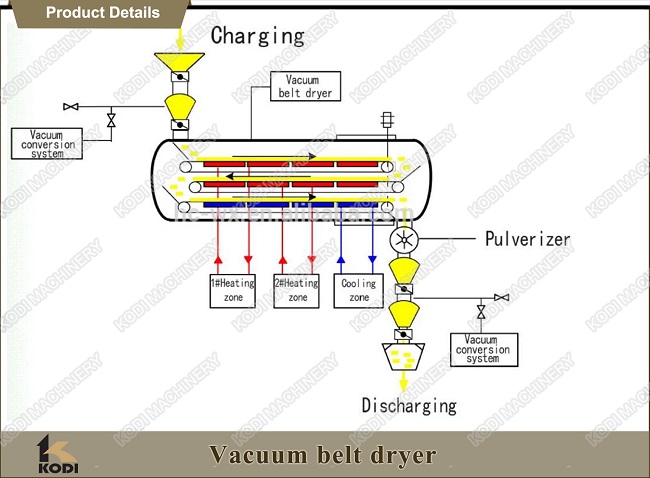

The material to be dried is sent into the vacuum chamber of the dryer through a screw metering pump, and is evenly shoaled on a conveyor belt by a distribution motor. The motor-driven special roller drives the conveyor belt and runs at the set speed. Below the conveyor belt, there are independent heating plates and a set of cooling plates. The conveyor belt is closely attached to the heating plates and the cooling plates, and the heat required for drying is transferred to the materials and cooled in a contact heat transfer manner. The speed of the conveyor is set according to the nature of the material. When the material is transported from one end of the barrel to the other by the conveyor, the material has been dried and cooled. When the conveyor belt is folded back, the dried cake is peeled from the conveyor belt. After being pulverized by the pulverizing device, the granules obtained through the butterfly valve airlock can be directly made into capsules or tablets.

Technical characteristics of vacuum belt dryer

(1) Low drying temperature, low energy consumption, no pollution, continuous production, automatic control, and meet GMP requirements;

(2) Dry at low temperature, and can be adjusted with different materials (35 ℃ —90 ℃);

(3) There is a certain degree of crystallization during the drying process of the product. After crushing, the pellets have good fluidity and can be directly filled into capsules;

(4) The feeding speed can be precisely adjusted, and the feeding device can evenly distribute even when the feeding amount is small;

(5) Each conveyor belt in the box is individually controlled by a variable frequency motor;

(6) Automatic granulation, dry granules are continuously discharged into the storage bin under vacuum, and the dry granule storage bin can be replaced during the automatic drying process;

(7) Low energy consumption and low noise;

(8) The equipment can be cleaned in place with CIP and has a high degree of hygiene;

(9) The movement of the conveyor belt is controlled by a frequency-conversion speed-regulating motor, which has the functions of deviation correction and tension adjustment;

(10) The tank is equipped with a stirring device and a constant temperature device, which can be heated and mixed when adding auxiliary materials;

(11) PC-based control system with friendly man-machine interface, convenient operation and flexible modification of process parameters;

(12) Conveyor with a variety of specifications from 1 to 10 layers, tailor-made according to user requirements;

Product specifications and technical indicators of belt vacuum continuous dryer

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

|

Serial number |

2 |

6 |

10 |

30 |

50 |

60 |

80 |

100 |

120 |

150 |

200 |

|

Model |

VBD2-4-2 |

VBD6-4-2 |

VBD10-4-2 |

VBD30-5-3 |

VBD50-5-5 |

VBD60-5-4 |

VBD80-5-5 |

VBD100-5-6 |

VBD120-6-6 |

VBD150-6-8 |

VBD190-6-10 |

|

VBDBasic situation of the host |

|||||||||||

|

Total heating area/m2 |

2.11 |

6.08 |

10.64 |

31.05 |

51.7 |

60.72 |

79.35 |

101.84 |

122.54 |

152.35 |

204.24 |

|

Heating plate width/mm |

440 |

800 |

950 |

1150 |

1150 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

|

Heating plate length/mm |

600 |

950 |

140 |

1800 |

1800 |

2300 |

2300 |

2500 |

2500 |

2300 |

2500 |

|

Cooling plate width/mm |

440 |

800 |

950 |

1150 |

1150 |

1380 |

1380 |

1380 |

1380 |

1380 |

1380 |

|

Cooling plate length/mm |

600 |

950 |

1400 |

1800 |

1800 |

1800 |

2300 |

2300 |

2300 |

2300 |

2300 |

|

Number of districts |

4 |

4 |

4 |

5 |

5 |

5 |

5 |

5 |

6 |

6 |

6 |

|

Number of straps (number of layers) |

2 |

2 |

2 |

3 |

5 |

4 |

5 |

6 |

6 |

8 |

10 |

|

Inner diameter of barrel/mm |

900 |

1400 |

1400 |

1800 |

2300 |

2300 |

2500 |

2500 |

2500 |

2800 |

2800 |

|

Tube length/mm |

4.1 |

5.5 |

7.3 |

10.9 |

10.9 |

13.9 |

13.5 |

14.3 |

16.9 |

15.9 |

15.9 |

|

Number of heating plates |

8 |

8 |

8 |

15 |

25 |

20 |

25 |

30 |

36 |

48 |

60 |

Remark: 1. Parameters above in the table are regular model for reference;

2. We could make special model / size according to the customer's actual situation or requirement, please contact KODI sales team to konw more details about industrial food dryer.

Simple Drawing of Industrial Continuous Conveyor Vacuum Belt Dryer

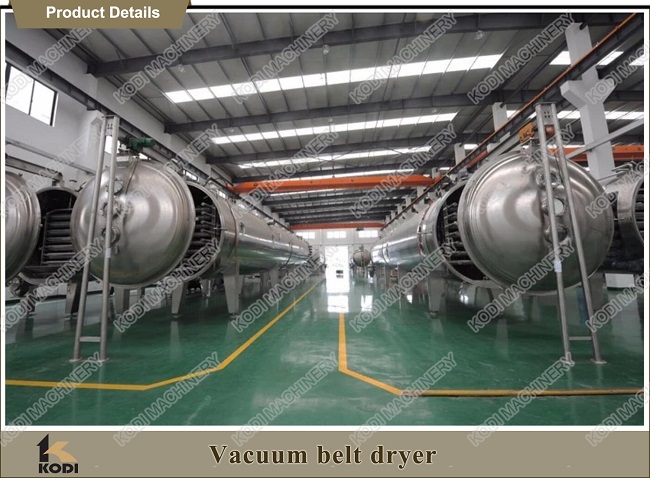

Packaging & Shipment of Industrial Continuous Conveyor Vacuum Belt Dryer