Changzhou Kodi Machinery Co.,Ltd.

Marketing office: 7F, Tongjiang Road 398-1#, Xinbei District, Changzhou 213022 China

Factory address:Zhenglu Industrial Park, Changzhou, Jiangsu, China

Tel: +86 (519) 8696 5716

Fax: +86 (519) 8918 5716

Hotline: +86 15995073588

E-mail: info@kodichina.com

Web: www.kodichina.com

Vacuum Tray Dryer Description

In the drying chamber, material will be dried under vacuum condition. Under the vacuum condition, the boiling point of material solution will reduce. It will increase impetus for heat and mass exchange. Therefore for certain heat exchange amount, it can save heat exchange area of evaporator

Material is under static condition during operation of the equipment, which is benefit for keeping initial status of material. Intermittent operation can adjust process conditions at any time.

On the top of vacuum dryer, heating system is arranged to tackle the problem of return of condensed water, in addition, air suction is arranged at the side to improve drying efficiency.

This equipment can be used for low temperature drying and organic solvent recovery. Heat source can be steam, hot water and thermal oil. It is specially suitable for drying materials that is easily oxygenated during drying.

Vacuum Tray Dryer Application

It is Suitable for drying of thermal sensitive materials easily resolved. Polymerized or deteriorated under higher temperature and it is wide used in pharmaceutical, chemical, foodstuff and electronic industries.

Details of Vacuum Tray Dryer

Vacuum Tray Dryer Features

1. It can get higher drying capacity at lower temperature and the heat energy can be used fully.

2. It is suitable for materials such as heat sensitive and easy oxidizable material.

3. It can dry raw materials that contain solvent and which needs to be recovered.

4. Before drying, it can carry out disinfectant treatment. During the period of drying, any impurity can not enter it.

5. The dryer belongs to static drying, materials will not be damaged.

6. The machine is a kind of batch type operation and can adjust technical process at any time.

7. The inner top is designed arch structure, it can effectively avoid the condensed water drop back.

8. Vacuumize from 4 points to one point, can guarantee uniform drying.

Vacuum Tray Dryer Working Principle

It is well known that vacuum drying is to put raw material to the state of vacuum for heating and drying . if use vacuum to take air and humidity out, the dry speed will be faster.

Note: if use condenser, the solvent in raw material can be recovered. The condenser can be substituted by SK series water-ring vacuum pump or ZSWJ series hydropower spray vacuum pump unit if available.

Vacuum Tray Dryer Flow Chart

Successful Experience Overseas of KODI Vacuum Tray Dryer

Vacuum tray dryer has a very mature technology and process, and KODI company has rich overseas site installation experience and good after sale service.

Vacuum Tray Dryer Delivery and Packing

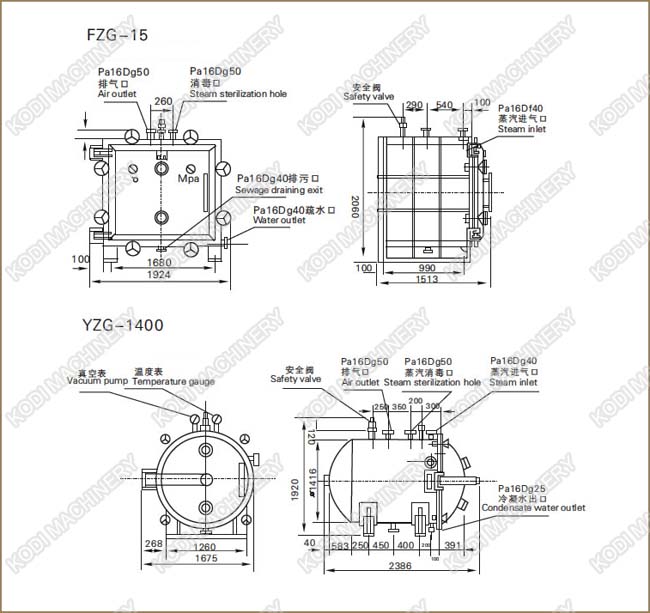

Vacuum Tray Dryer Technical Parameters

|

Model Item |

YZG-600 |

YZG-800 |

YZG-1000

|

YZG-1400 |

|

Inner size of drying chamber(mm) |

600×976 |

800×1247 |

1000×1527 |

1400×2054 |

|

Outer size of drying chamber(mm) |

1153×810×1020 |

1700×1045×1335 |

1693×1190×1500 |

2386×1657×1920 |

|

Layers of backing support |

4 |

4 |

6 |

8 |

|

interval(mm) |

81 |

82 |

102 |

102 |

|

Size of baking tray(mm) |

310×600×45 |

520×410×45 |

520×410×45 |

460×640×45 |

|

Quantity of baking tray |

4 |

8 |

12 |

32 |

|

Working pressure inside the pipe of baking support(MPa) |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

|

Temperature inside the chamber(°C) |

≤150 |

≤150 |

≤150 |

≤150 |

|

Degree of vacuum inside the chamber when operation in idle, MPa |

≤30 |

|||

|

Under the vacuum condition of 30and110°C ,evaporation rate of water(kg/m2,h) |

7.2 |

|||

|

Model and power of vacuum pump when condenser is used(kw) |

2X-15A 2kw |

2X-30A 3kw |

2X-15A 3kw |

2X-70A 5.5kw |

|

Weight of drying chamber(kg) |

250 |

|

800 |

1000 |

|

Model Item |

FZG-10 |

FZG-15 |

FZG-20 |

|

Inner size of drying chamber(mm) |

1500×1060×1220 |

1500×1400×1220 |

1500×1800×1220 |

|

Outer size of drying chamber(mm) |

1924×1720×1513 |

1513×1924×2060 |

1924×2500×1513 |

|

Layers of backing support |

5 |

8 |

12 |

|

interval(mm) |

122 |

122 |

122 |

|

Size of baking tray(mm) |

460×640×45 |

460×640×45 |

460×640×45 |

|

Quantity of baking tray |

20 |

32 |

48 |

|

Working pressure inside the pipe of baking support(MPa) |

≤0.784 |

≤0.784 |

≤0.784 |

|

Temperature inside the chamber(°C) |

≤150 |

≤150 |

≤150 |

|

Degree of vacuum inside the chamber when operation in idle, MPa |

≤30 |

||

|

Under the vacuum condition of 30and110°C ,evaporation rate of water(kg/m2,h) |

7.2 |

||

|

Model and power of vacuum pump when condenser is used(kw) |

2X-70A 5.5kw |

2X-70A 7.5kw |

2X-70A 7.5kw |

|

Weight of drying chamber(kg) |

|

2100 |

|